Crane Pre-Use Visual Inspection Checklist (Pad of 30)

£8.09 VAT excl.£9.71

- Description

- Order your free sample

- How to use

- FAQs

- Want to customise?

- Shipping & Returns

Pendant cranes (also called overhead and bridge cranes) are used across a wide variety of heavy industries to serve as the lifting equipment. Overhead cranes require routine inspection and maintenance to ensure a long life of safe and reliable lifting.

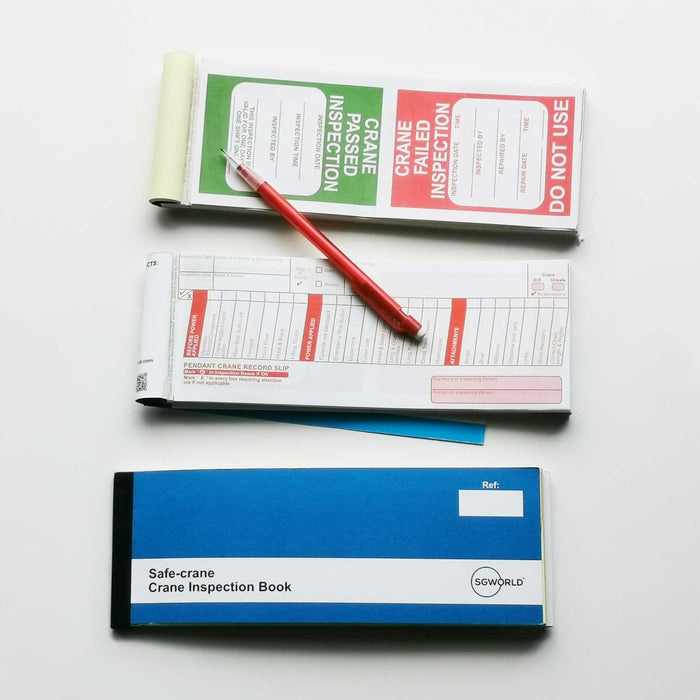

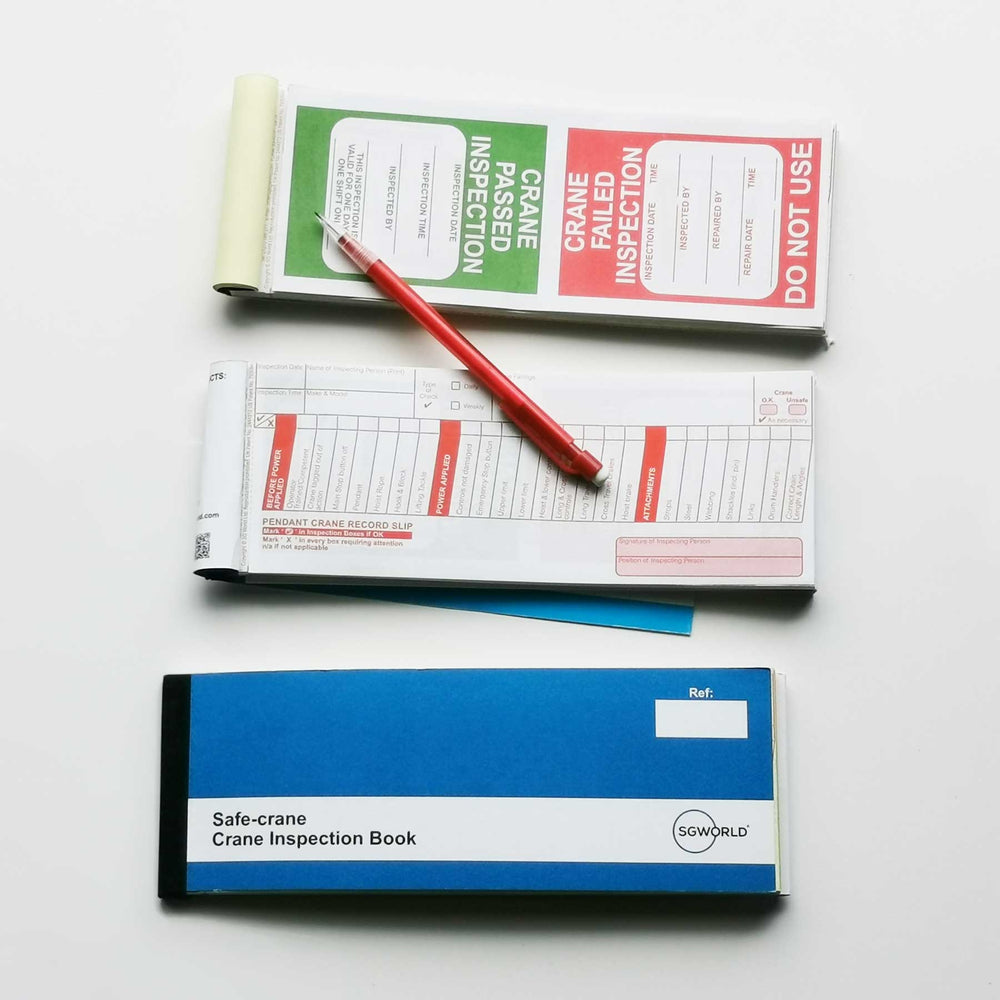

The crane inspection pad enables an organisation to work through a duplicate checklist and carry out an inspection of a pendant crane, ensuring that is is safe for use. The top copy of the checklist is displayed on the crane controls to indicate its safety. The duplicate copy remains fast in the pad as evidence that the inspection has taken place in the event of an HSE investigation.

Dimensions: 84mm (h) x 229mm (w)

Order our free sample pack and take one for a test drive

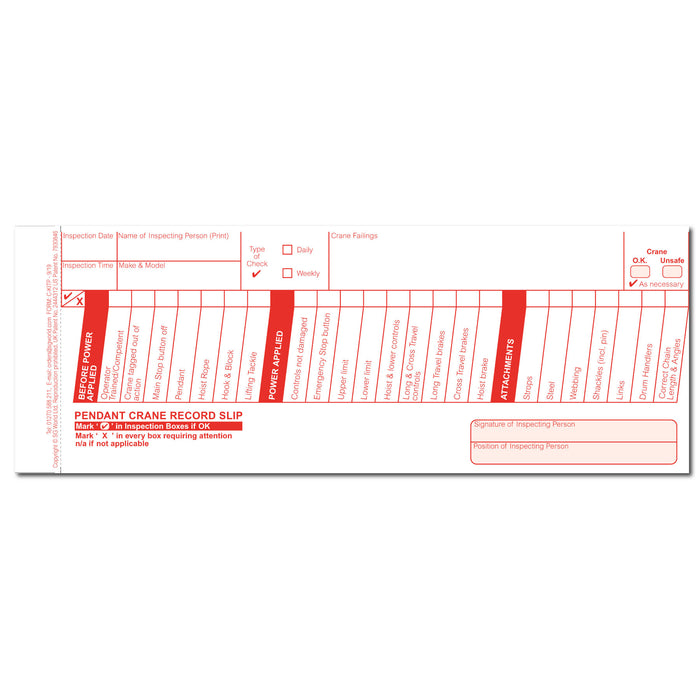

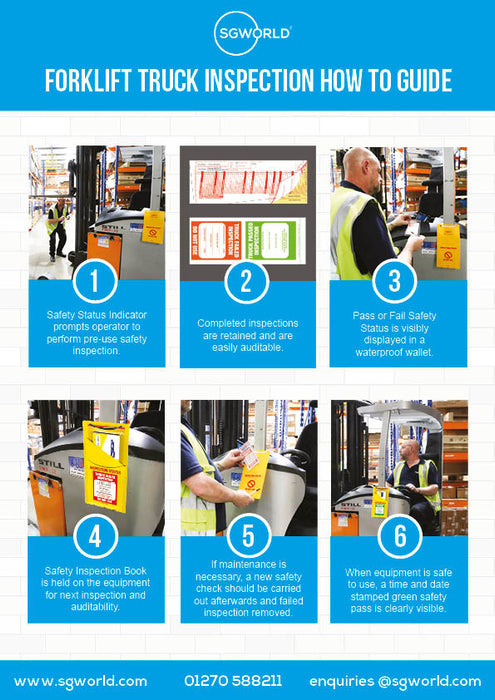

The crane operator simply works down the inspection checklist, checking the safety of each component in turn. Once the inspection is complete, assuming safety has been established, the green PASS inspection certificate can be placed inside a safety status indicator on the crane control area ensuring that everyone can clearly see that the crane is safe for use. A faulty crane can be similarly identified by a red FAIL certificate and reported for maintenance. The duplicate copy of the certificate remains inside the inspection pad and can be used as evidence of inspections should you ever need to produce this for the HSE or other official parties.

Who should undertake an overhead/pendant crane's safety inspections and maintenance checks?

The crane’s day to day operational safety checks are generally carried out by the crane operator working from the overhead crane safety inspection checklist. All checks should be listed and ticked when completed. Safety concerns should be noted. If remedial safety work is required prior to operation, this should be noted, completed, and signed off by the qualified person/engineer. Periodic inspection/maintenance checks should always be undertaken by competent engineers or fitters.

How often should a pendant or overhead crane be inspected?

Your overhead crane inspection frequency should be defined in the overhead crane safety inspection checklist to ensure that it is completely clear and your inspections remain consistent. In addition to the normal operating safety checks, there should be periodic detailed inspection and maintenance checks undertaken by a fully qualified engineer or competent person. This can be anything from monthly to bi-annually, or annually depending on the model, workload and environment.

Check out our full range of pre-use safety inspection articles and guides.

Looks good but need something personalised for you and your workplace? Check out our customisation options.

SG World have in-house expertise in design, print and software development, so if you’re looking for something with your personal branding, a quick format tweak or a complete re-design, we have the experience and resources in place to quickly transform an idea into a practical solution. Complete our Contact Us form here and we’ll be in touch to discuss your ideas.

SHIPPING AND RETURNS POLICY

Please note - Custom / branded products may take up to 15 days to manufacture from proof approval

SHIPPING OPTIONS:

- Standard £10.95

- Express 1-2 Days £14.95

Please be aware SG World does not despatch orders on a Friday, orders placed on Friday will be posted on the following Monday for Tuesday delivery.

Items can be returned and refunded minus a handling fee in a good condition, un-used and un-opened. The return delivery charge will not be refunded unless the return is due to damaged goods or a mistake by SG World Ltd.

Credit Notes will be processed once the goods are received back by us, and until this time, they remain your property. We highly recommend using a 'signed for' return delivery service such as Royal Mail Recorded Delivery.

Imprinted and Special made to order items will not accepted for return under any circumstances.