MEWP Pre-Use Visual Inspection Checklist (Pad of 30)

£8.09 VAT excl.£9.71

- Description

- Order your free sample

- How to use

- FAQs

- Want to customise?

- Shipping & Returns

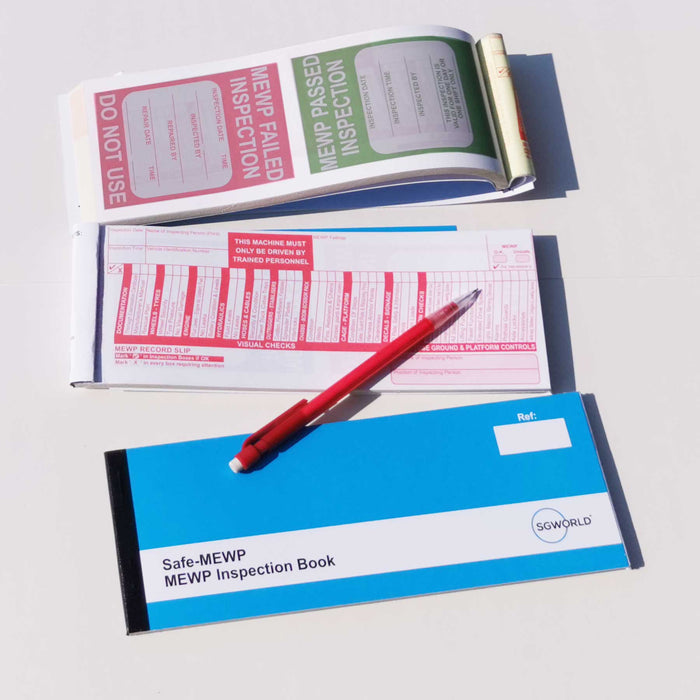

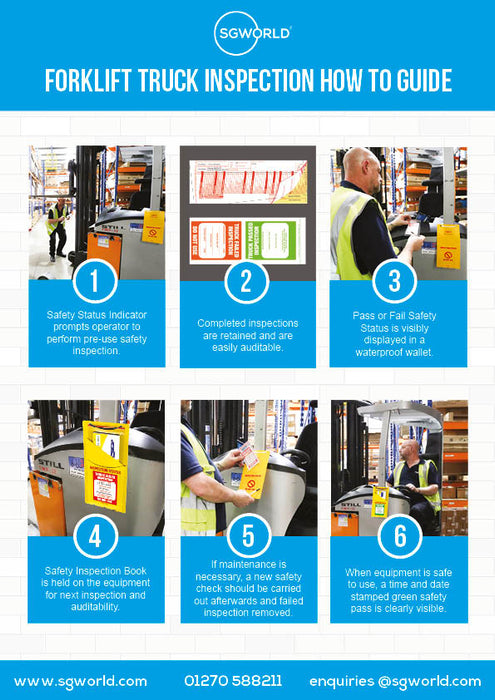

MEWPs can be one of the most dangerous pieces of equipment on your site. Ensuring that they’re inspected regularly for safety helps to reduce the possibility of accidents occurring. The MEWP inspection pad helps businesses perform their pre-use or daily safety inspections. The checklist is designed to help you comply with your duty of care under HSE guidance L117 and PUWER. The duplicate checklist design creates two signed copies of each inspection and incorporates a PASS/FAIL notice. Each pad has 30 checklists and is used in tandem with a hi-vis display wallet

Our checklists are suitable for use with any standard MEWP including Genie, Manitou Skyjack and Niftylift.

Dimensions: 84mm (h) x 229mm (w)

Order our free sample pack and take one for a test drive

If you've got any other questions you can check out our How To Page for more information.

What does MEWP mean?

A MEWP is a Mobile Elevating Work Platform. MEWPs have two basic categories, boom such as cherry pickers and vertical lift such as scissor lifts.

What is a MEWP pre-use check?

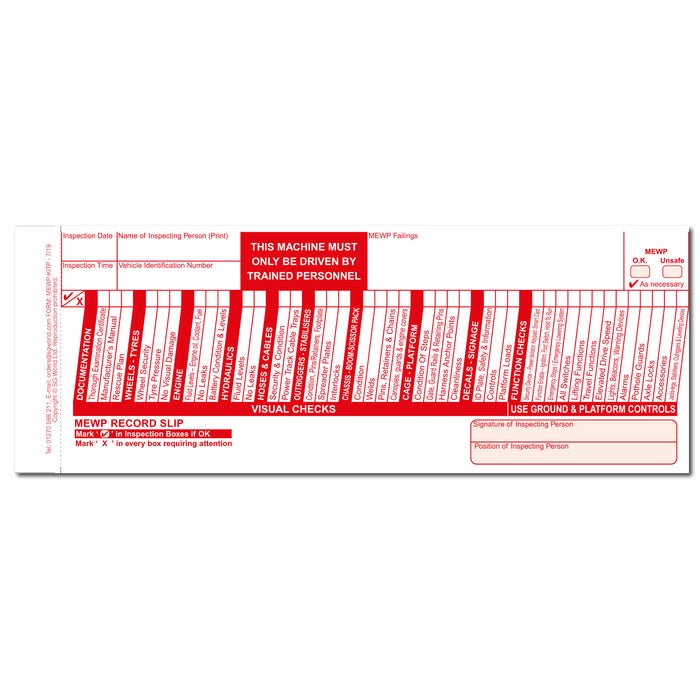

The MEWP operator is responsible for carrying out a basic daily/pre-use function check. These checks will confirm that the machinery is safe to operate and identify any potential hazards it may pose before the work at height is carried out. Records of these checks should be kept. Checks usually include visual and function checks covering areas such as:

Controls – Test all lift controls before any people or equipment are raised from the ground. This should include cut out switches and emergency stop mechanisms.

Hydraulic fluid and petrol – The oil level in the tank should be full when the platform is on a level surface and there should be enough fuel in the tank to complete the job.

Maintenance – Check the vehicle for any signs of damage or age which might cause it to malfunction. This should include identifying damaged or loose hoses or fittings, rust, corrosion, holes and electrical faults.

Stability – For a mobile access platform, the brakes of the vehicle should be fully functional. The base of a powered access platform needs to be locked into position before the platform is extended or elevated. Check all stabiliser legs and extendable parts are operational before use.

For more information check out our blog on M

How often do MEWPS need to be inspected?

The HSE recommends that a programme of daily visual checks, regular inspections and servicing schedules should be established in accordance with the manufacturer’s instructions and the risks associated with each MEWP.

A thorough examination must be carried out every six months by a competent person, or at an increased frequency in accordance with an examination scheme drawn up by such a competent person.

For more information check out our blog on M

Looks good but need something personalised for you and your workplace? Check out our customisation options.

SG World have in-house expertise in design, print and software development, so if you’re looking for something with your personal branding, a quick format tweak or a complete re-design, we have the experience and resources in place to quickly transform an idea into a practical solution. Complete our Contact Us form here and we’ll be in touch to discuss your ideas.

SHIPPING AND RETURNS POLICY

Please note - Custom / branded products may take up to 15 days to manufacture from proof approval

SHIPPING OPTIONS:

- Standard £10.95

- Express 1-2 Days £14.95

Please be aware SG World does not despatch orders on a Friday, orders placed on Friday will be posted on the following Monday for Tuesday delivery.

Items can be returned and refunded minus a handling fee in a good condition, un-used and un-opened. The return delivery charge will not be refunded unless the return is due to damaged goods or a mistake by SG World Ltd.

Credit Notes will be processed once the goods are received back by us, and until this time, they remain your property. We highly recommend using a 'signed for' return delivery service such as Royal Mail Recorded Delivery.

Imprinted and Special made to order items will not accepted for return under any circumstances.