Pallet Racking Pre-Use Visual Inspection Checklist System (Pad of 30)

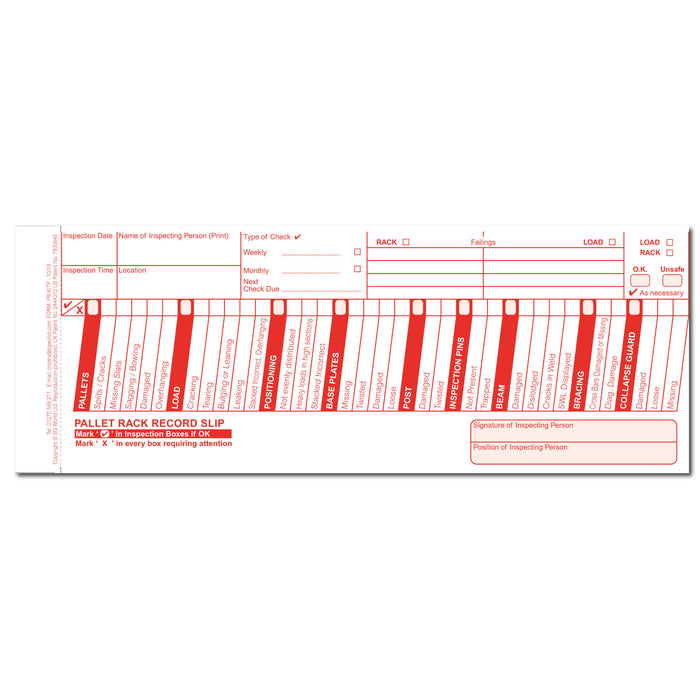

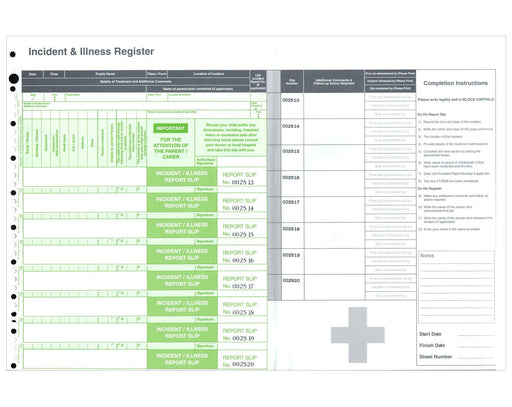

Wherever you find fork lift trucks, you usually find pallet racking. Considering the weight each section of racking supports and the chances of collision with a fork lift, it’s important that the racking is regularly inspected and checked so that there is no chance of collapse. The pallet racking inspection pad helps businesses perform their pre-use or daily safety inspections. The checklist is designed to help you comply with your duty of care under HSE guidance and PUWER. The duplicate checklist design creates two signed copies of each inspection and incorporates a PASS/FAIL notice. Each pad has 30 checklists and is used in tandem with a hi-vis display wallet

Dimensions: 84mm (h) x 229mm (w)

Order your free sample

Order our free sample pack and take one for a test drive

How to use

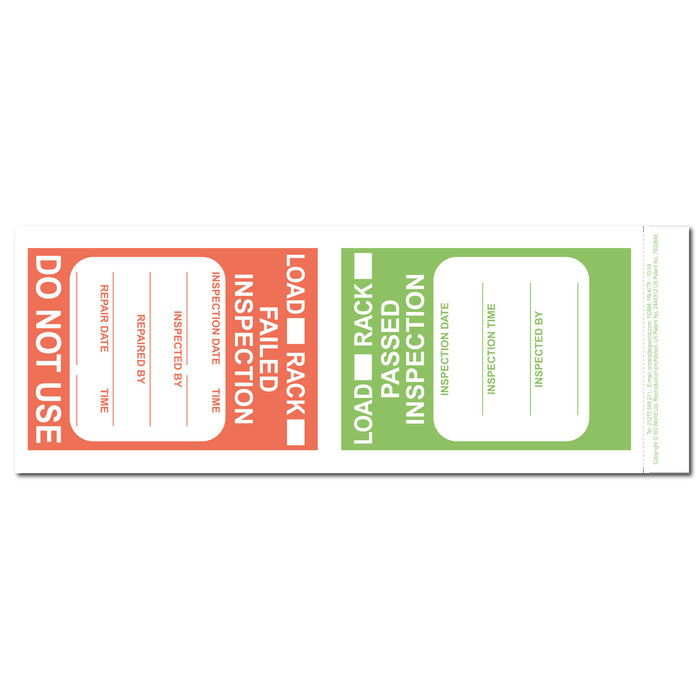

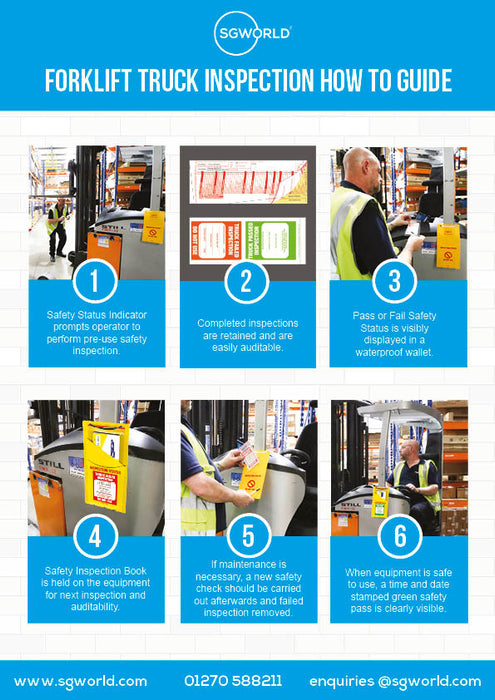

On a regular or weekly basis the nominated person responsible for racking safety can simply work down the inspection checklist, checking the safety of each component in turn. Once the inspection is complete, assuming safety has been established, the green PASS inspection certificate can be placed inside a safety status indicator on the racking ensuring that everyone can clearly see that it is safe for use. Failing racking can be similarly identified by a red FAIL certificate and reported for maintenance. The duplicate copy of the certificate remains inside the inspection pad and can be used as evidence of inspections should you ever need to produce this for the HSE or other official parties.

If you've got any other questions you can check out our How To Page for more information.

FAQs

How often should racking be inspected?

The HSE guidance HSG75, the recommendation is that a racking inspection by a SEMA approved inspector at least once a year for all warehouses in the UK, as well as weekly racking inspections from a “technically competent” staff member.

Is it a legal requirement to have racking inspected?

No BUT the HSE guidance in HSG75 recommends a racking inspection by a SEMA approved inspector at least once a year as well as weekly racking inspections from a “technically competent” staff member. Whilst this is not actually law, the HSE guidance is intended as an easy-to-understand reference guide and it's advice is accepted best practice which should normally ensure you are complying with wider Health and Safety legislation such as PUWER and the HASAW 1974.

Want to customise?

Looks good but need something personalised for you and your workplace? Check out our customisation options.

SG World have in-house expertise in design, print and software development, so if you’re looking for something with your personal branding, a quick format tweak or a complete re-design, we have the experience and resources in place to quickly transform an idea into a practical solution. Complete our Contact Us form here and we’ll be in touch to discuss your ideas.